Automation in hospitals

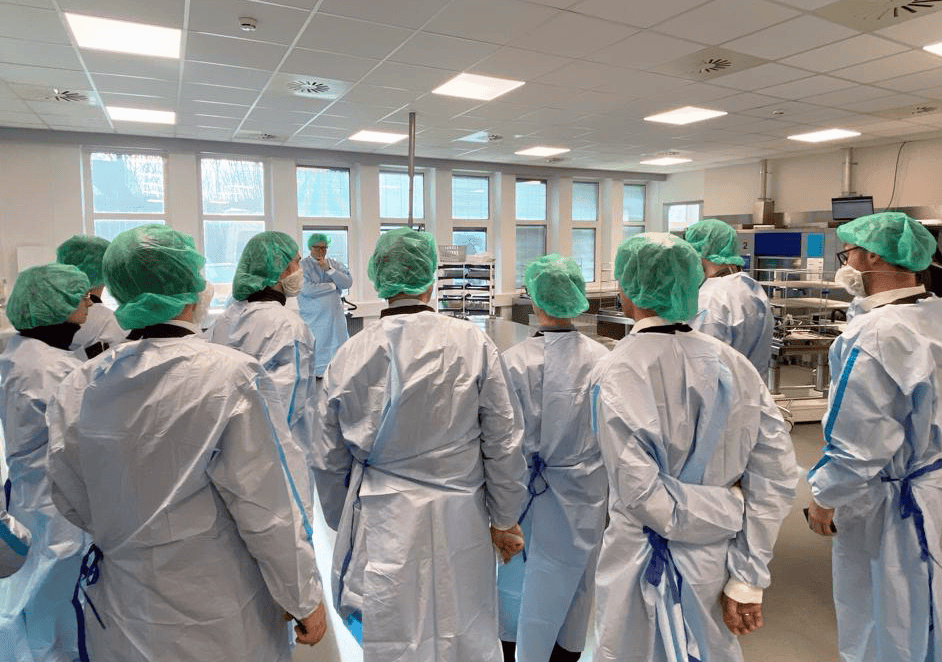

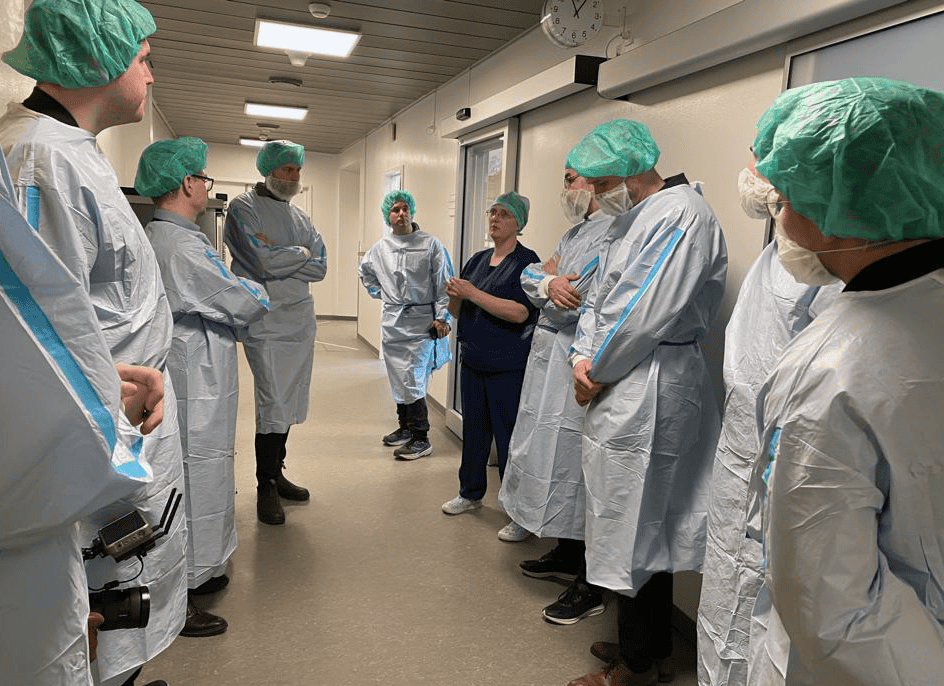

How can you improve internal logistics in a hospital’s sterile center? Robotics companies from across Denmark spent two days at a hospital in Southern Jutland together with hospital staff getting to know the challenges and identifying automation solutions.

A unique opportunity

The six companies left the Sprint having forged new connections and discussed new solutions for the sterile center department, while Sygehus Sonderjylland was presented with new ideas that could be relevant for their future development.

Not only does a Sprint provide Sygehus Sonderjylland with a unique opportunity to develop customised solutions for their specific problems, but it also offers the participating companies the chance to enter new industries and have a close interaction with customers in an intensive process to rethink already known technology in a new and innovative way.

A win-win opportunity for all parties.

What do the participants say

Solving real challenges

It is very interesting to be allowed to open our doors and describe the challenges that we have to companies. And then take the opportunity to see, whether we can solve our challenges with new technology or with existing technology put together in a new way,”

Thomas Nis Lorenzen, Logistic Manager at Sygehus Sonderjylland

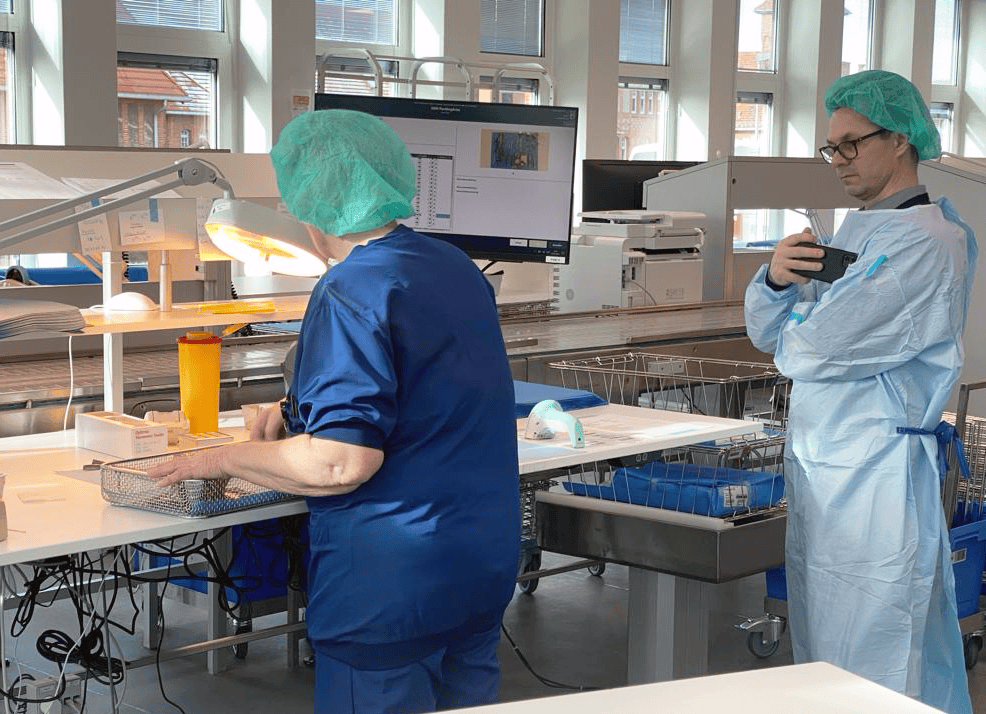

First hand experience

“We have been able to use our knowledge and design a solution for the project here in the hospital. It’s been great to be able to talk to the staff and see the facilities for ourselves,”

Jürg Meier, Senior Project Manager at Project Partners

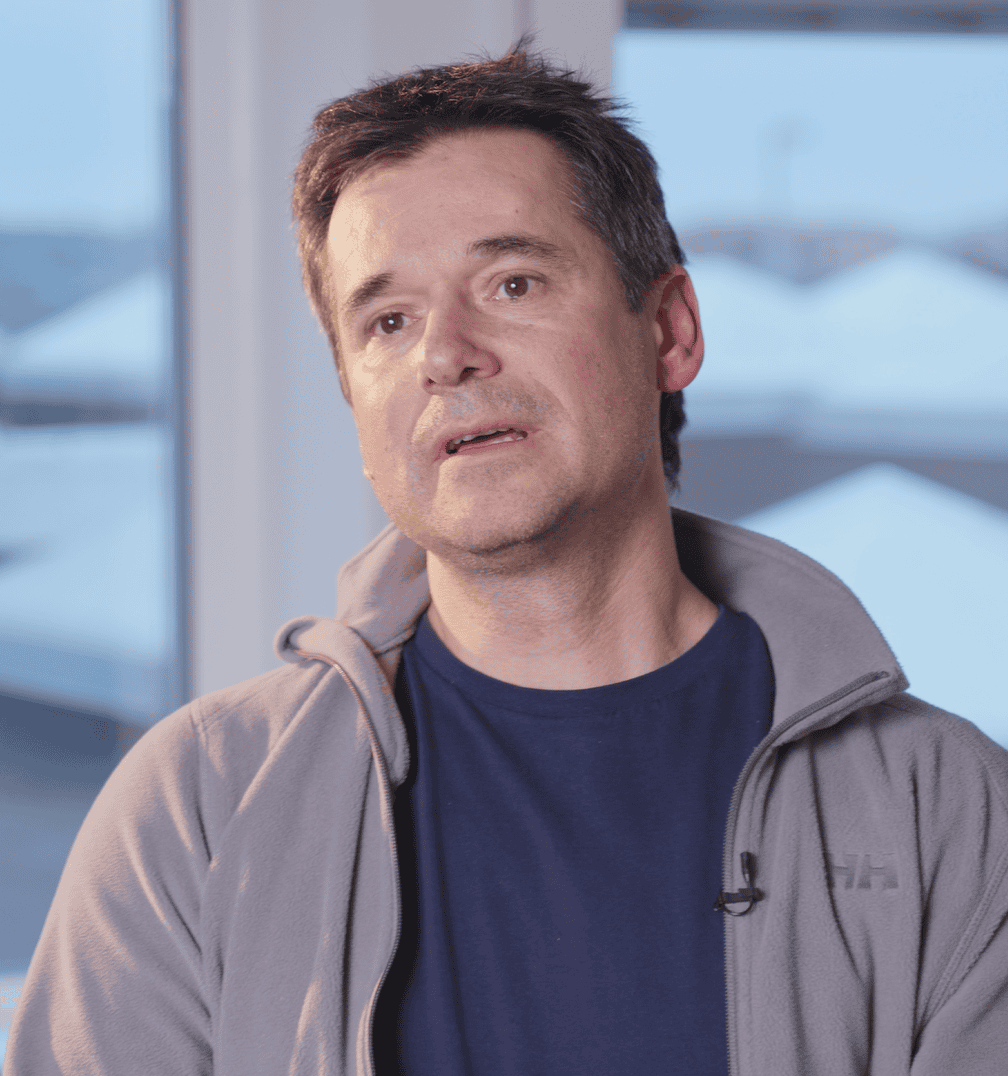

New market opportunities

“This has given us the opportunity to get closer to the customer and see the challenges in its real-life setting. If we came here by ourselves, there would not be allocated the same time and same resources. We get way more out of this model, where you are part of a planned setup,”

Palle Veje, Business Development Logistic at Omron